With more than three decades of experience, Algom specializes in the design and production of industrial rubber seals and rubber-to-metal molded parts.

Algom is a leading manufacturer of industrial rubber seals and rubber-to-metal molded parts designed to last and withstand extreme conditions. We offer customized solutions for industries such as automotive, marine and food.

Al-gom specializes in the production of industrial rubber gaskets. With more than 30 years of experience, the company follows the entire production cycle: mold design, compound formulation, and manufacture of the gasket, even in large sizes.

Al-gom's production can count on hundreds of compounds for making gaskets: the wide range includes fluorinated (Viton®), also in GLT, AED, and HNBR formulations, as well as compounds ideal for food specifications or specially formulated compounds.

Al-gom works with full respect for the environment, the workplace and its employees, espousing the principles that govern regulations to protect safety and professional ethics. Since 2009, the company has been certified according to UNI EN ISO 9001:2015.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Each solution we offer follows a well-defined process, ensuring a smooth experience and results that live up to expectations.

We develop custom rubber compounds to meet the technical needs of various industries. From the selection of materials to the composition of compounds, each stage is carefully managed to ensure a high-quality end product.

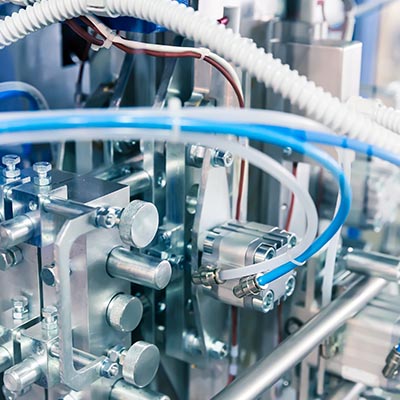

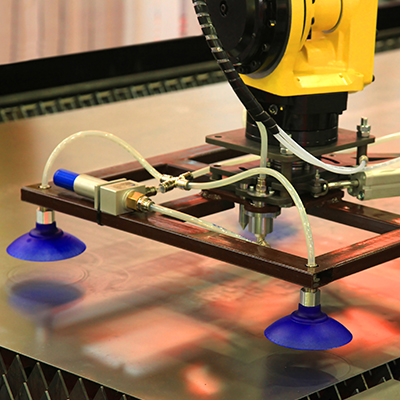

We use state-of-the-art technologies for process control and production. Our plants and machinery ensure precise and optimized production, reducing error margins and improving overall quality.

We offer a comprehensive consulting service, accompanying clients from the design phase to the production phase, ensuring specific and optimized technical solutions for each project.

Via Vanzago, 16 25030 Paratico, (BS)

Monday - Friday

8 am - 12 pm

1:30 pm - 5:30 pm

For 39 years, passion and professionalism in manufacturing industrial co-molded gaskets

rubber-metal.

P.I. 03296710175 | C.F. 01682050164

Via Vanzago, 16 25030 Paratico, (BS)